With the supply chains breaking due to the #covid-19 pandemic, some resources are becoming hard to procure. But there are cases when someone’s health or even life, depends on these limited resources. Being a 3D Printer owner, I realise that this is a valuable asset for building things that are otherwise hard to get. Take a face mask for example. With all the 3D printers out there owned by individuals, corporations or makerspaces, we can produce more masks than we could use.

The requirements:

- Design a 3D mask that is cheap and only takes a 3D printer and some filament to make

- Make it offer the best protection

- Make it use air-filters that are 1) easy to procure (even with the curent crises) and 2) are easy to replace

- The mask can be disinfected for continuous use

- The mask is comfortable to wear

- The mask is attached hermitically to the face

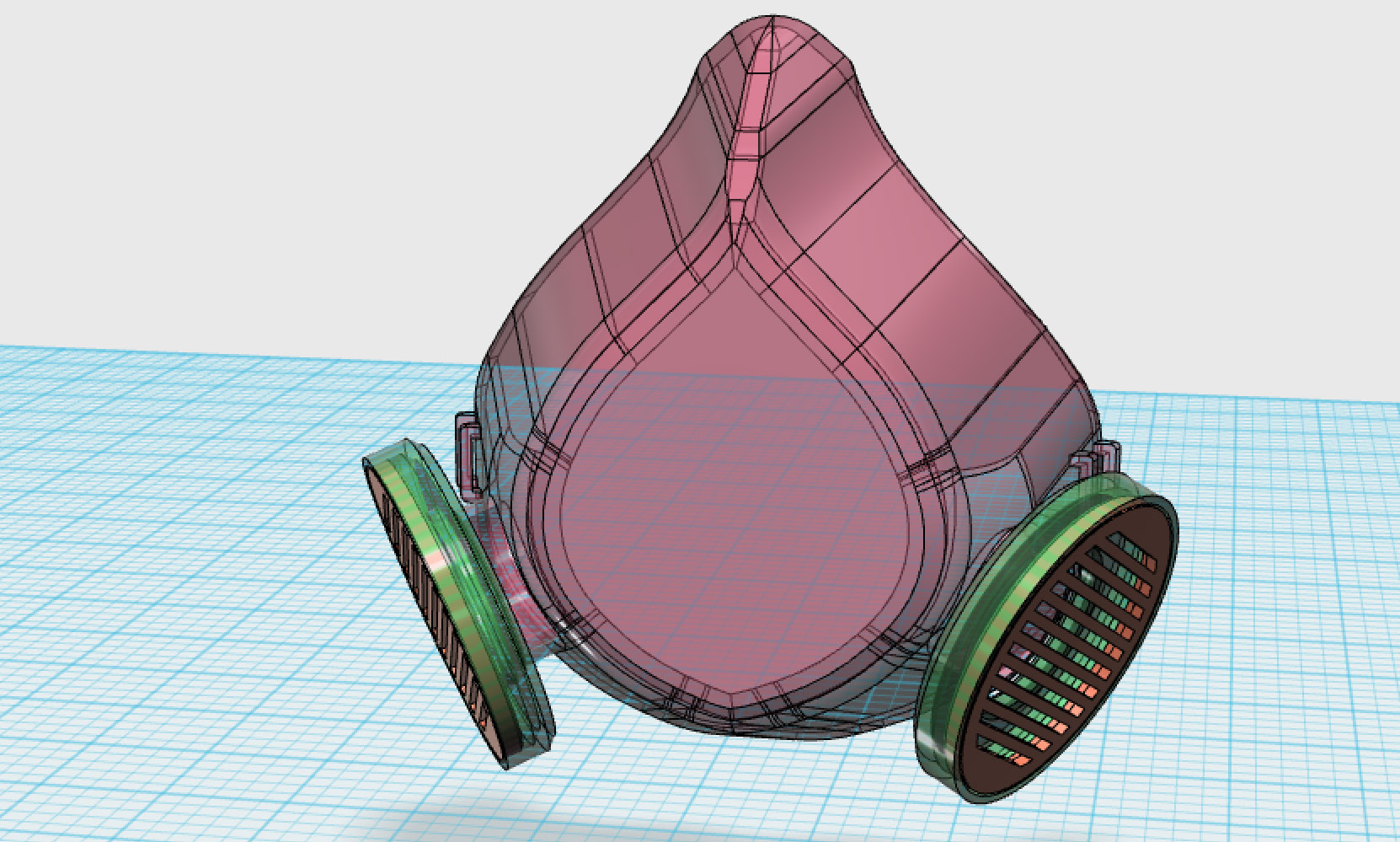

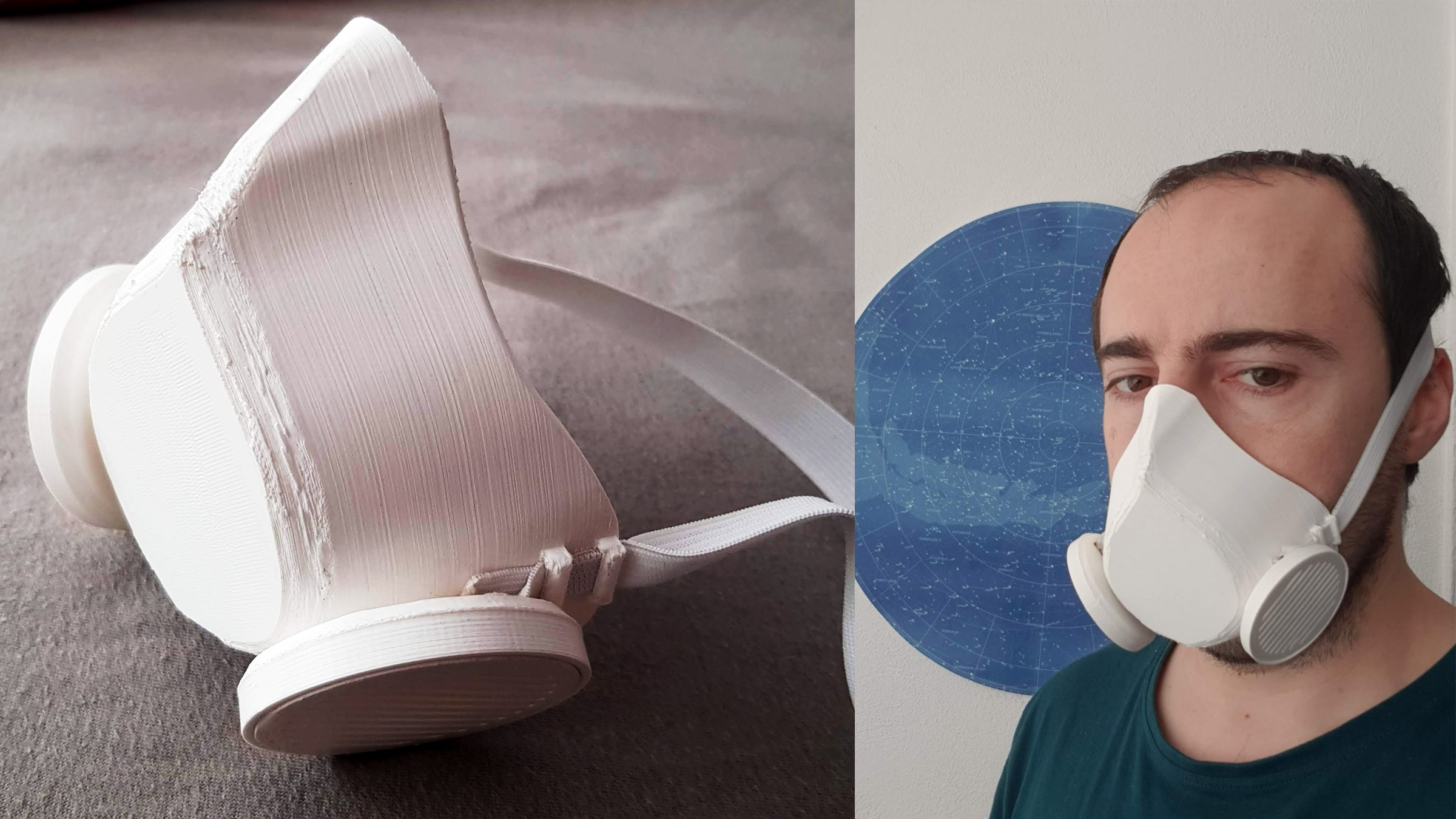

Apparently, all these are possible, despite the long list. I designed a 3D printable mask, that weights only 60grams. The cost of 60grams of PLA plastic is about 1USD at ardushop. There are already several great designs on thingverse, but this is probably the first to use a adhesive sponge to increase comfort and seal it to the face:

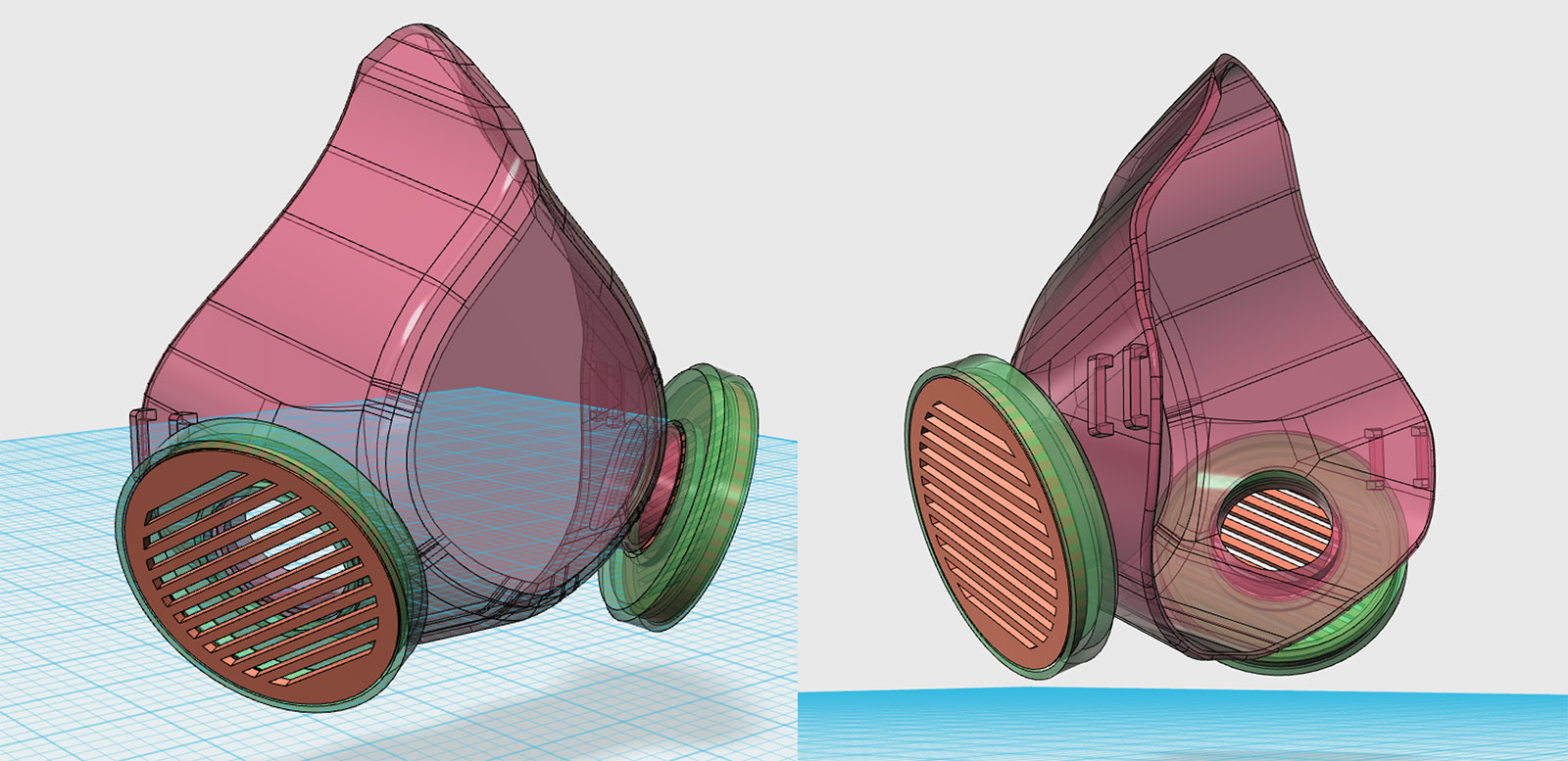

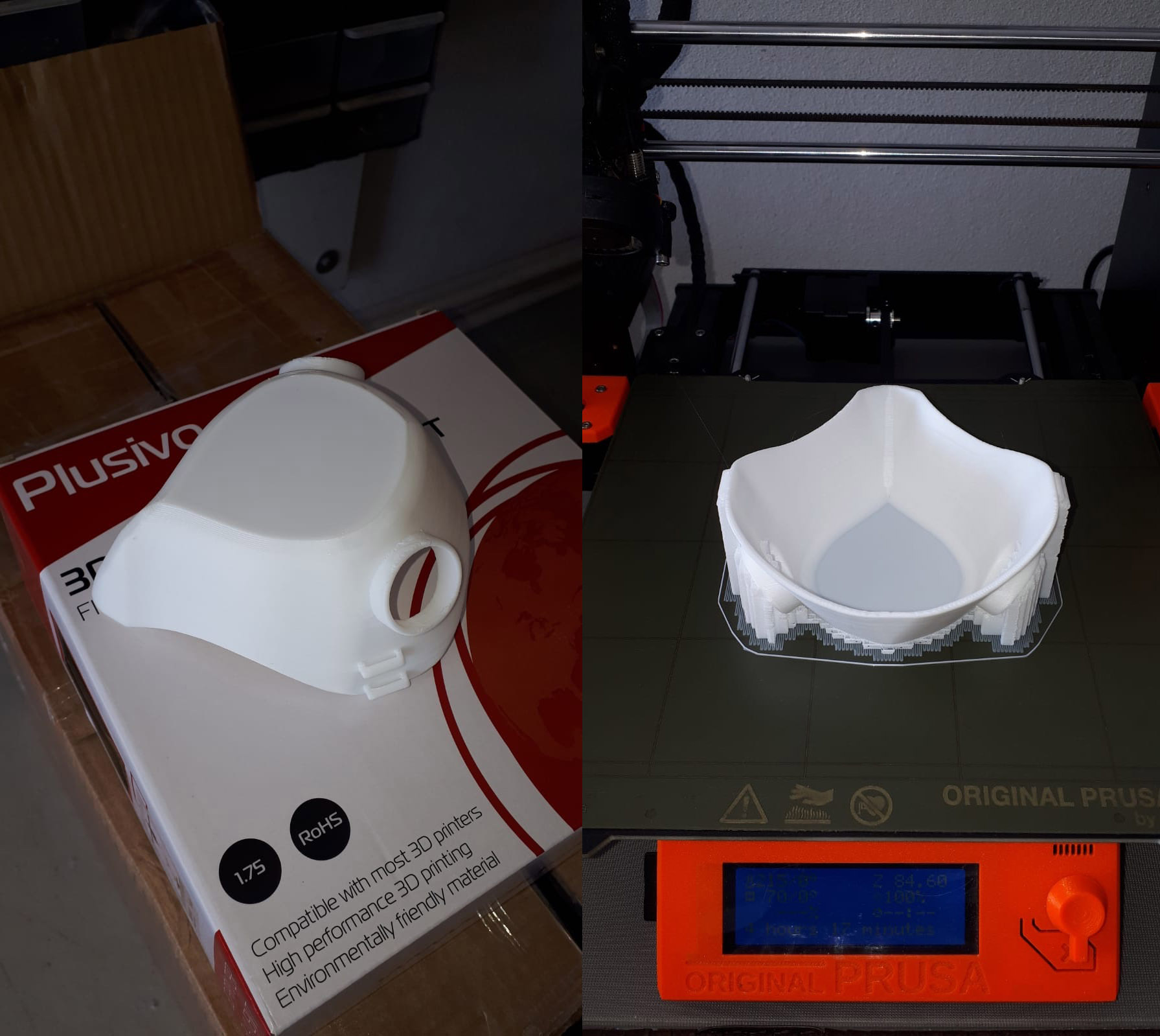

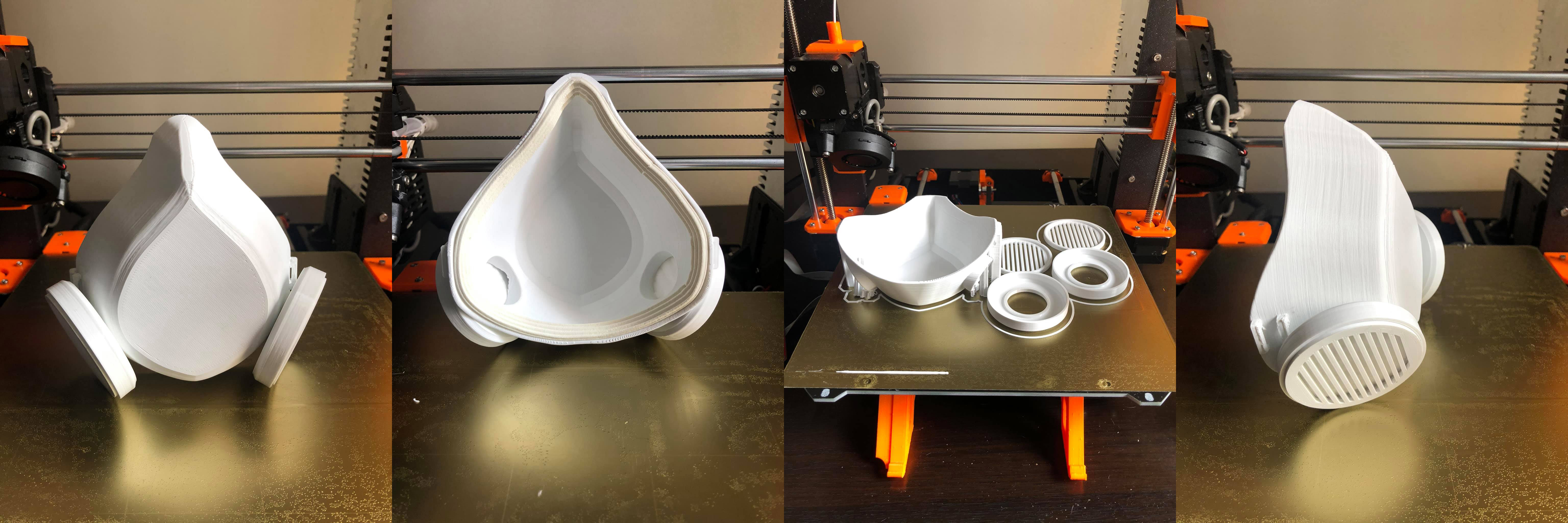

The design started with a pyramid and other primitives that were further processed to match the curvature of an adult male’s face. The filter containers were designed with openings to allow air flow while keeping the filters in place:

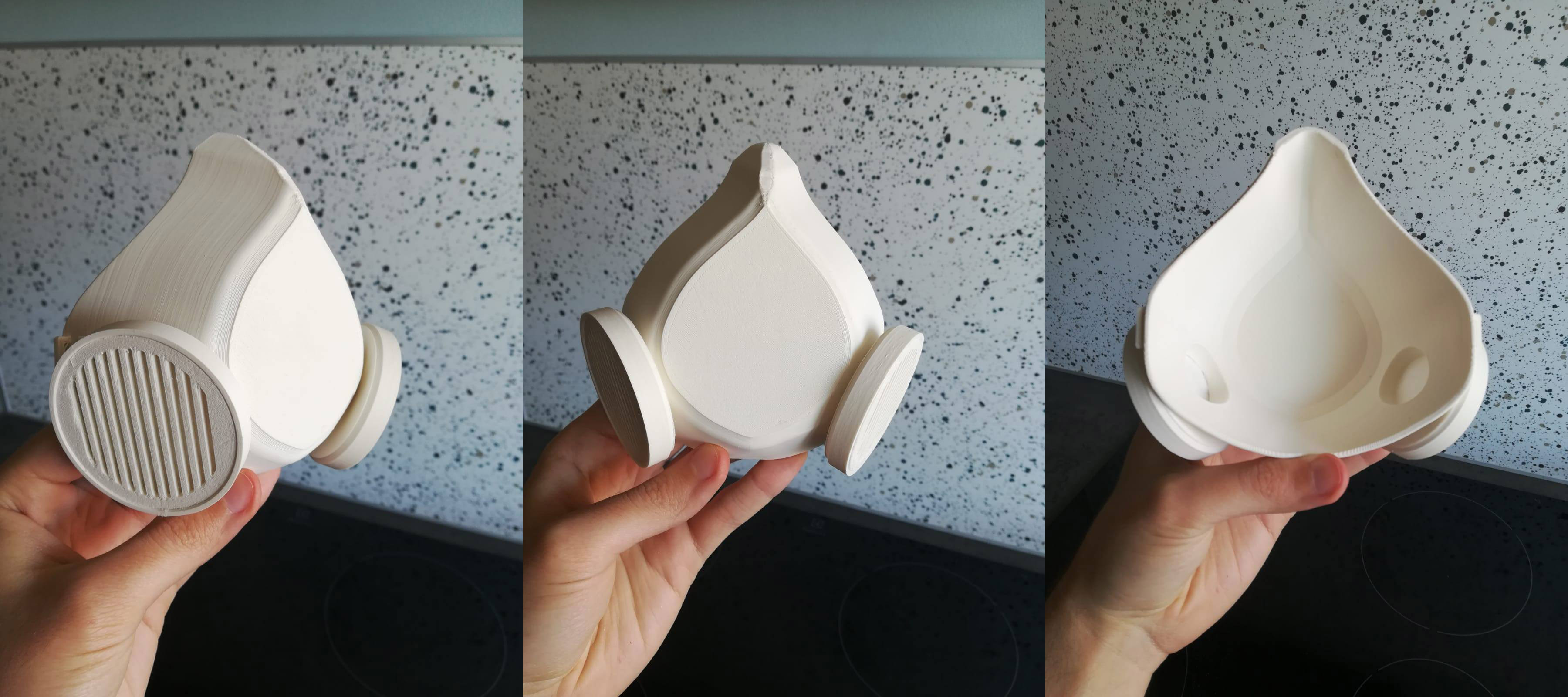

Print times at 0.3 resolution: 1h30min for 2x Filter containers + 2x Filter caps and 3h30min for the mask. Here are the results, including the rubber band:

Performance tests

Here’s a video (in Romanian) about how 3D printing is done, how well are welded together the layers that make up the mask, a water test, images under the microscope and finally, a test with a thermal imaging camera that shows where the air comes in and where the air goes out to illustrate the face sealing performance.

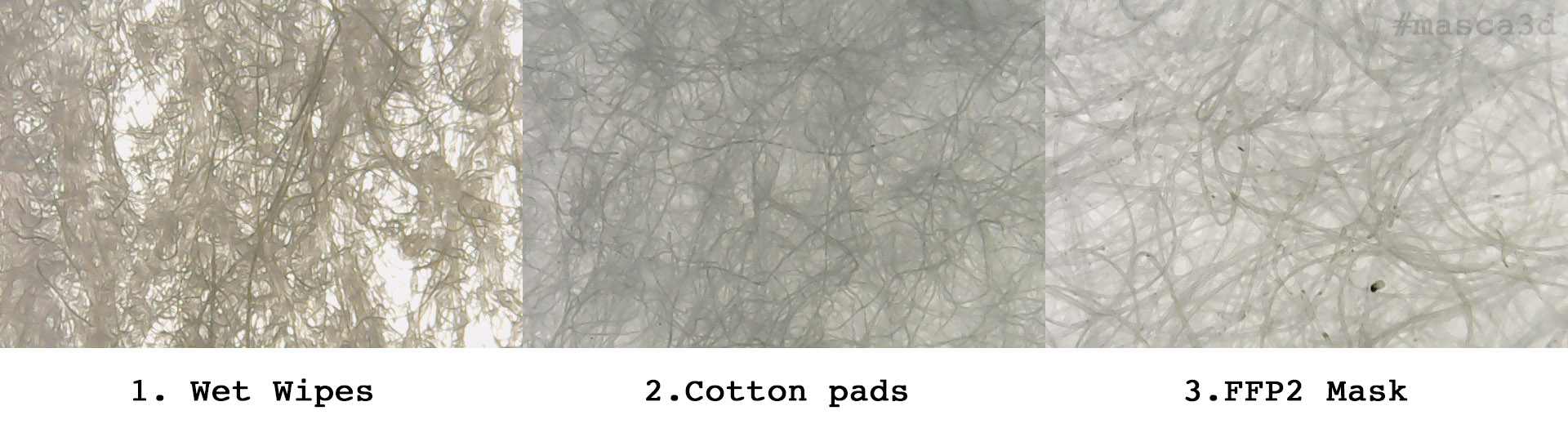

Filters under the microscope

You all know about FFP2 masks like the one below:

There are also wet wipes that some suggested they could be used for filters (packed in several layers). How do all these compare? Here are some microscope pictures, showing the differences. All of them are taken against a powerful light source, so any openings in fabric would show right away.

For all three materials the same settings were used: same background light intensity and distance from source to probe, same microscope magnification.

The Wet Wipes have some big problems, and I don’t think they are suitable for air filtering: the fibres are rare, light protrudes straight through (so will the particles), dragging it even slightly will cause more openings. Also, unless it is washed and dried, there will also be emollients and chemicals clogging the fibres and eventually getting to your lungs. I wouldn’t use this.

The cotton pads have thin and dense fibres. Most important they are long so it is unlikely they will easily detach and fly to your lungs. Light doesn’t get through, meaning the filter has no openings, and the absorbed light going through the opaque disk indicated a good thickness.

The FFP2 Mask comes with long plastic fibres. These will surely work great for trapping incoming particles since an electrostatic effect will easily develop on plastic (also on cotton). They are not so dense as the cotton pads so small particles can find a way easier then through the cotton pads. Also more light propagates through the opaque material as in the case of the cotton disk.

How’s the winner here? Check the photos and decide for yourself. It is obvious the cotton disks are a nice alternative, easy to procure and easy to replace. The mask’s containers allow for two stacked disks, doubling all this and exceeding the FFP2 by far.

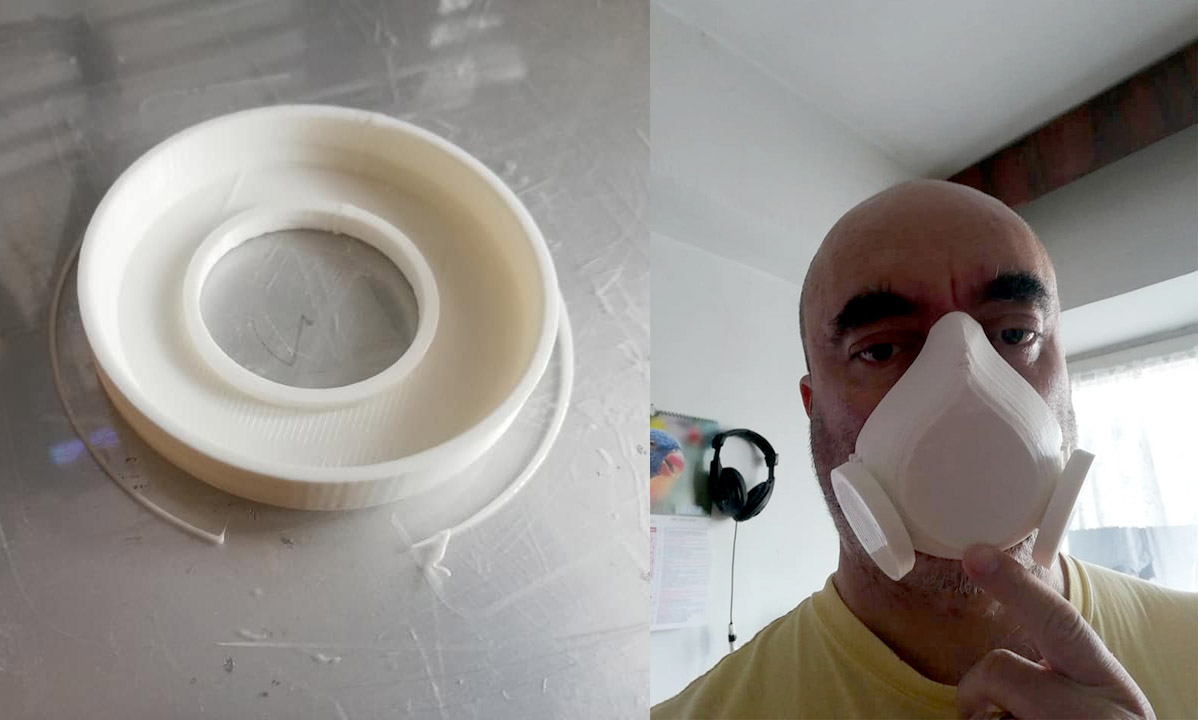

But there are many other options here. The containers can be customised for any filter combination, depending only on what it can be sourced on the local market and stock availability. For sensitive applications, instead of the existing containers, you can use HME filters , here’s an example made by Teo, who used two Draeger HME filters. Their datasheet indicates stopping 99.99% of viruses and bacteria. And they fit right away, with no other modifications:

Active filters

Another idea was to impregnate the cotton pads with anti-microbial chemicals, let them dry, then use them in the mask. When breathing, the the humidity in air would transfer to the chemicals, making them humid and active. I considered the following:

- Methylene Blue

- Rivanol

- Betadine

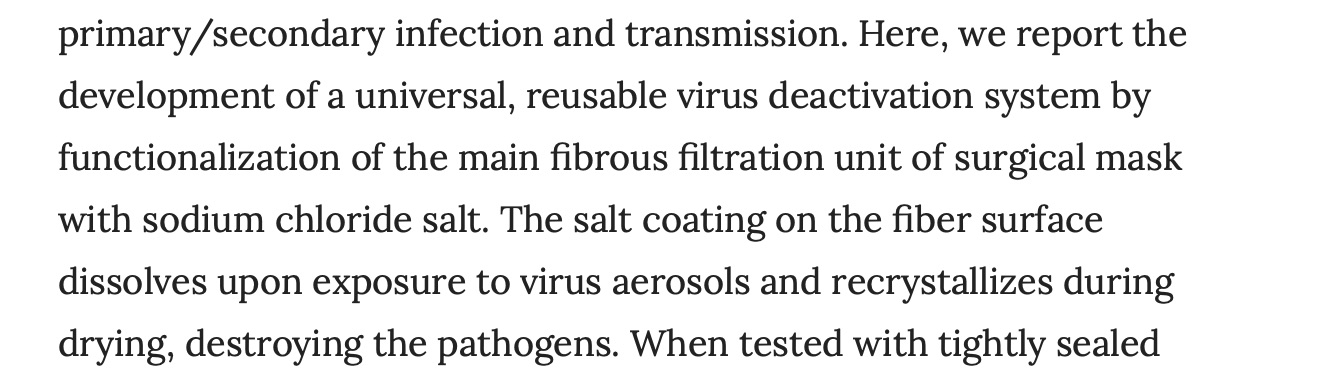

Sadly, all these are slightly toxic when inhaled, so it’s definitely not an option for a face mask filter. But then Ionut sent me this link in Nature.com.

The study shows that a saline solution can act as antimicrobial agent for a similar scenario – single use masks. The filters can be soaked in a saturated saline solution, left to dry, then inserted in the #masca3d filter container. The exhaled air will reactive the hygroscopic salt crystals and enable them to kill viruses. Other salts can be used as well and may have a better yield (Sodium bicarbonate).

Download the files:

The 3D model is available under CC-A license :

- direct download here

- download on Thingiverse.

Call to Action

Makers or makerspaces, use your tools to manufacture masks that can save a life and donate them to those in need. Post pictures with your results, or suggest improvements.

Updates and feedback

Makers started building their own masks and great feedback started to come. Here are a few builds:

2020-04-02, Cristi’s variant:

2020-04-02, Ovidiu, inventor of Chargie, started printing his #masca3d:

2020-04-03, #masca3d is on Hackaday.io! build one yourself!

I did a few tests to determine how comfortable the mask is when wearing it for a longer time. After 2hours there were no marks on my face, breathing was ok (yet, I could feel the air being limited due to filtration), there was a little condensation inside but the filters were still usable (not even a little moist). The rubber is important for comfort and so is the sponge band used to seal the mask to the face. Video in Romanian:

Mihai built his own mask and provided some valuable feedback: Apparently it would be best to have several sizes for this mask (S,M,L,XL) to better fit on various individuals.

2020-04-04, Andrei builts his own mask

Here’s another one built by Alex:

And Nicu’s is a good print too:

Mihai did a great job with his mask:

2020-04-05, More people are joining the effort!

Here’s Radu’s micro-factory, producing #masca3d at a fast pace. Congrats Radu!

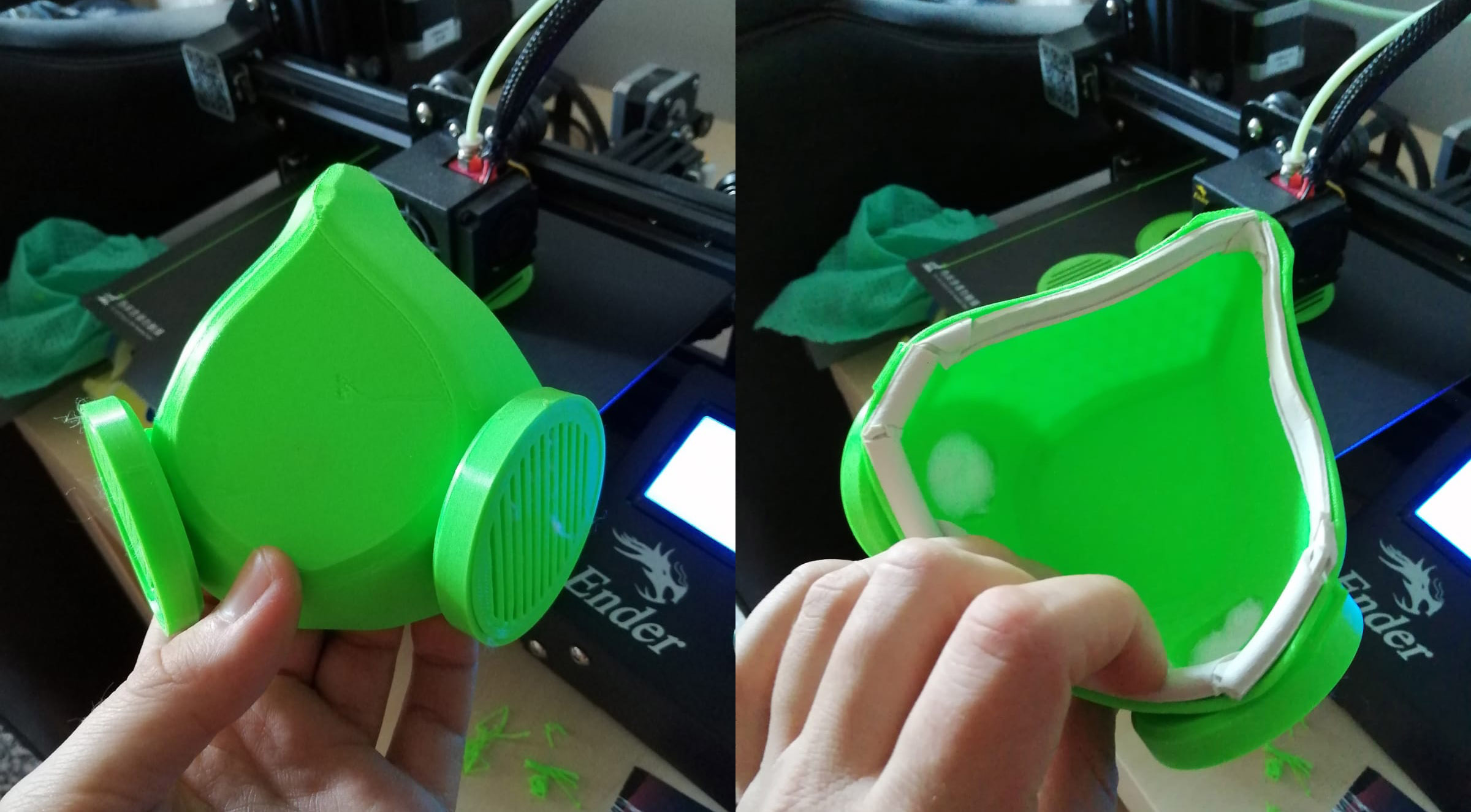

Lucian is making one for his wife, so he went for some nice colours for this mask:

Vali’s prints are excellent too:

2020-04-07, Gabriel made a video to show how the #masca3d 3dPrint works

Here’s the video:

Thank you Gabriel, this is very illustrative. The entire print takes about 3h30min, but here it was set on fast-forward. His mask came out very nicely too:

Congrats all! Your commitment and responsiveness is truly inspiring!

The Maker Movement

Just two days after publishing this simple 3d mask design it became adopted by lots of people. It is becoming obvious that the makers with their distributed resources totalise a production capacity worth taking into account.