With so many tutorials out there, so many opinions and also the multitude of printers and filaments available, why another guide? Well, because it is useful for me to keep track of all the issues, hence this blog post. And if useful for more, even better.

- Hole in the middle with ASA / ABS Filament

First layer starts nice, maybe the next 2-3 also go ok, but then parts of the inner material start to unstick.

Solution: lowering the BED Temperature from 105C to 90C solved the problem immediately. Maybe it is possible to help this issue by using better first-layer adhesives like (3DLAC, Magigoo, etc).

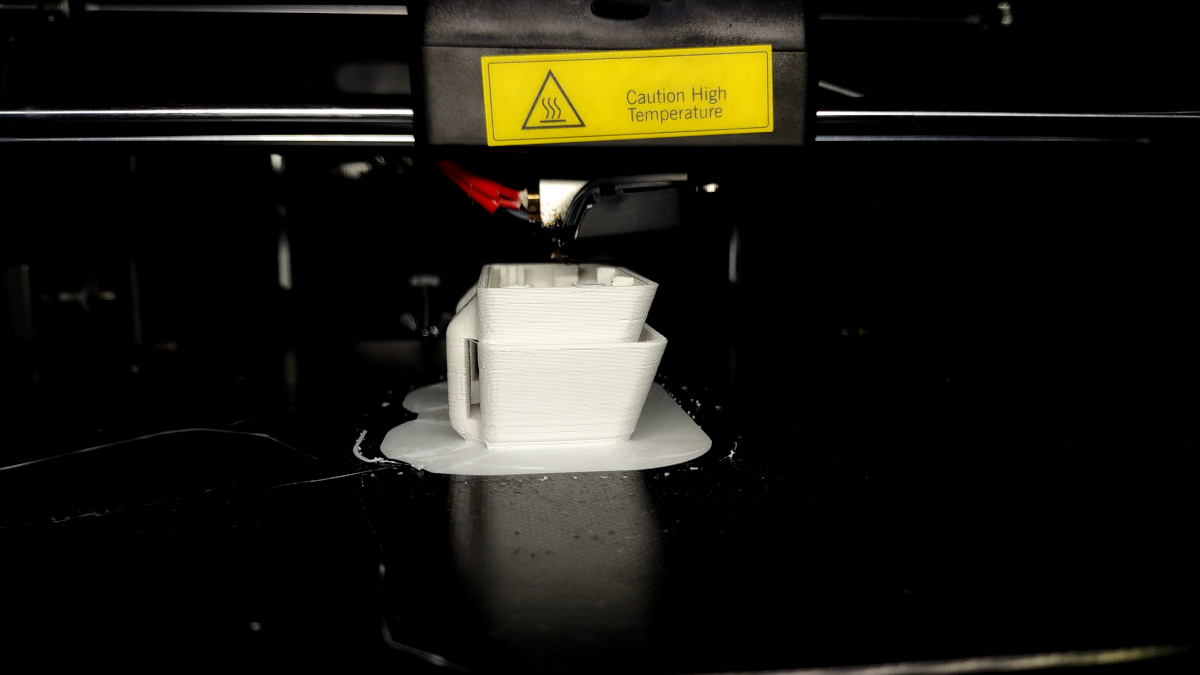

Settings that work: 255C nozzle (all layers), 90C bed (all layers), lower printing speeds of about 35-40mm/s. Layer adhesion could be improved, though, but still this print is much better:

- Shifting layers in 3D print

This usually happens when the nozzle hits a protuberance (hardened plastic, some garbage, etc) but it can be more serious than that. If every print comes shifted, it’s a problem with your axes, your belts or your pulleys. In my case below, the pulley of the Y axis came of its place as the fixing axis screws loosened. It randomly shifted my layers and at first I didn’t know why.

Solution: Easy, putting the culprit pulley back in its place and tightening the fixing screws solved it immediately.

More soon..